Department of Defense Laboratories

The Department’s Laboratories engage in activities ranging from basic research through defense system acquisition support to direct operational support of deployed warfighters. These Laboratories are comprised of dozens of facilities across 22 states, and employs tens of thousands of scientists and engineers, both civilian and military, public employees and contractors.

The Department Laboratories execute a substantial fraction of the Department’s S&T accounts, particularly in budget activities 6.2 and 6.3. In addition, they conduct substantial amounts of reimbursable research and development (R&D) for DoD and Intelligence Community customer organizations.

- TBA

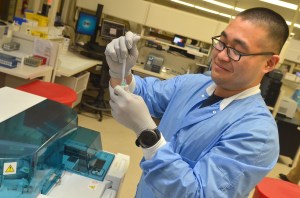

JACKSONVILLE, Fla. (April 23, 2018) Hospitalman Joseph Kim, a native of Dallas, Texas, draws serum into a cuvette at Naval Hospital Jacksonville’s laboratory. (U.S. Navy photo by Jacob Sippel, Naval Hospital Jacksonville/Released).

Air Force Labs

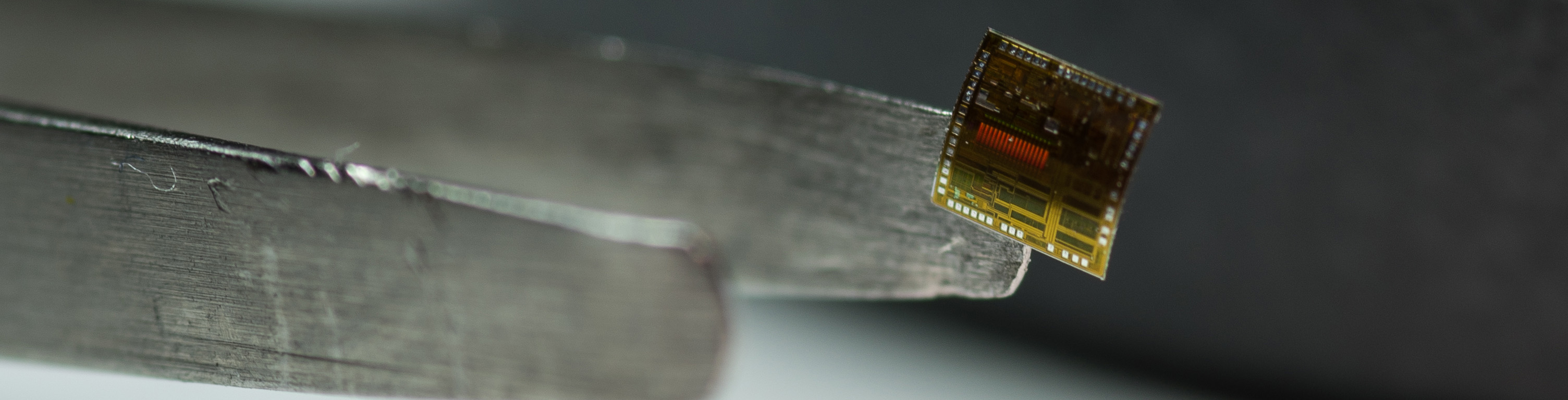

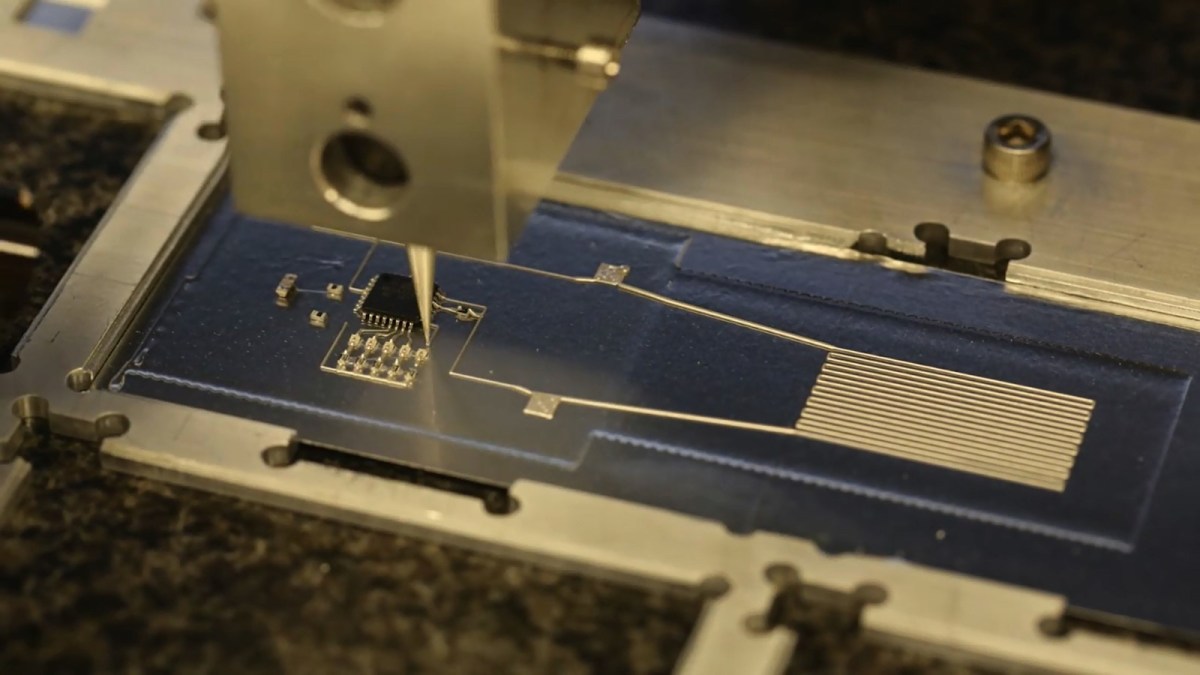

WRIGHT-PATTERSON AIR FORCE BASE, Ohio – A technique called Hybrid 3D Printing, developed by AFRL researchers in collaboration with the Wyss Institute at Harvard University, uses additive manufacturing to integrate soft, conductive inks with material substrates to create stretchable electronic devices. To create these, a 3-D printer prints conductive traces of flexible, silver-infused thermoplastic polyurethane (TPU). Then, a pick-and-place method using empty printer nozzles and a vacuum system sets microcontroller chips and LED lights into the flexible substrate. (Wyss Institute Courtesy Photo, 2017)

Army Labs

- Engineer Research and Development Center (ERDC)

- Army Medical Research and Materiel Command (MRMC)

- U.S. Army Research, Development and Engineering Command (RDECOM)

- Research Laboratory (ARL)

- Natick Soldier Research, Development and Engineering Center (NSRDEC)

- Armament Research, Development and Engineering Center (ARDEC)

- Tank Automotive Research, Development and Engineering Center (TARDEC)

- Communications-Electronics Research, Development and Engineering Center (CERDEC)

- Aviation & Missile Research, Development & Engineering Center (AMRDEC)

- Edgewood Chemical Biological Center (ECBC)

- Army Materiel Systems Analysis Activity (AMSAA)

The ARES optical system, developed by the NSWCDD, is mounted on ARDEC’s Picatinny Lightweight Remote Weapon System and coupled with an M240B crew-served weapon. These are two of three subsystems that make up the Wingman. (U.S. Army photo by Keith Briggs, TARDEC Ground Vehicle Robotics)

JACKSONVILLE, Fla. (May 10, 2018) (left to right) Sports Medicine Physician Lt. Cmdr. Kevin Bernstein, with Family Medicine Physicians Lt. Kerry Sadler and Lt. Paul Seales, examine a patient's knee at Naval Hospital Jacksonville's family medicine clinic. (U.S. Navy photo by Jacob Sippel, Naval Hospital Jacksonville/Released).